PRODUCTS

Bricks

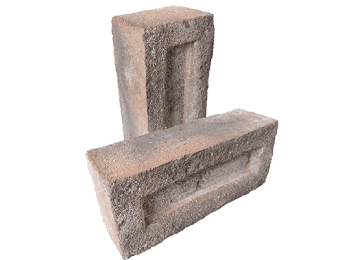

1. Wire Cut Bricks

Wire Cut Bricks are the bricks made by forcing stiff clay through a mold to create a uniform column & further this column is passed against steel wires to create a uniform size & shape. These extruded bricks tend to be more regular in size & texture than sand molded or handmade bricks.

They are very good in strength, durability & insulation properties. They may have perforations (holes) or may not (solid). The introduction of such holes reduces the volume of clay needed, hence the cost. These holes allow mortar to lock the bricks together when they are laid.

Multiple holes or perforations in bricks make them lighter in weight & parallelly increases their strength. Because of perforations, medium for conduction of heat collapses which gives good thermal insulation. They have been observed as a good sound insulator as well. Perforated Bricks

can be easily joined by mortar by simply placing a net on the surface where mortar need to be poured, which not only joins the two adjacent bricks but also restricts the mortar to fell in the cavities of the bricks retaining their holes vacant. These bricks are intentionally crafted to keep exposed to the environment without concealing them with plaster or color. Hence need no plastering or coloring which saves the capital & also gives the walls a terrific aesthetic appearance. Theses bricks lasts for centuries with no aging or fading of shades & blends. They are resistant to fire as well.

The insulation property of the bricks can also be enhanced by filling the holes with good insulation materials. As they are non – combustible in nature, they can be used in fire walls & fire barriers. The perforations in bricks can be horizontal or vertical in single or multiple patterns. They have high compressive strength & absorbs least water.

‘The Brick House’ offer huge varieties of Wire cut bricks with respect to sizes, shapes, colors, surface textures, fuels used for baking & type of perforation. These perforations may be cylindrical, square or rectangular. Our bricks are crafted on advanced machines, giving them a high level of

precision & consistency.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

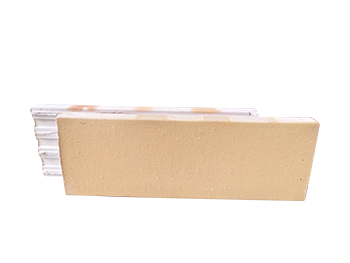

2. Press Bricks

Press Bricks (Hydraulic Press Bricks or Façade Bricks) are the bricks made by pressing clay in mold cavity under a high hydraulic pressure. These bricks are used to construct the brick walls that are intentionally left uncovered by plaster or paint (they can be painted if required), and are used as decorative elements to provide structural support. They can be used in both internal & external spaces, and can complement a variety of architectural designs. They are durable to withstand weathering & thus gives a vintage feel to structure. Each piece of Exposed Press Brick is unique as it leaves a unique distinctive imprint & appearance while baking in furnace.

Press Bricks, also known as Facing bricks are manufactured to be used as facing, to give pleasant & aesthetic look on the exterior of the wall. These bricks are different from other structural brickwork and carry a very clean and even appearance. These are primarily made to provide enhanced technical performance. High compressive strength and low water absorption are two of the major qualities of these bricks. Facing bricks offer a range of designs and textures that bring personality to a static structure, hence significantly increases the sale price of the property.

These are best suited for Arches, pillars & dome as well. They never contribute to fire & have improved thermal insulation. Facing bricks require zero maintenance and any other kind of expenses. Additionally, it

also prevents from rotting, warping, denting, fading, rusting, peeling or termites & are good energy efficient.

Press bricks (Engineered Bricks) can be used to create textured and colorful facades that stand out. These are very durable, fireproof, and long-lasting. They also provide insulation for sound & heat. Creativity is the major advantage of these bricks. They can be rotated, stacked, extruded & recessed to create texture & relief. They can also be joined together using different types of ties. The bricks are highly resistant to frost and impact.

‘The Brick House’ is a very well-known name for press bricks who offers 10+ varieties in Perforated or Solid Bricks. Colors we offer are Red, Terracotta, Beige, Grey, Chocolate, Brown, Multi-Color, Orange, Yellow, etc. Various sizes & shades are available to suit your mood & project. We can also alter & serve as per buyer’s requirement. No cracking, flaking or crumbling, just excellent bricks.

3. Hand Made Bricks

Handmade clay bricks or Rustic Bricks are made by mixing clay & water, then this semi compound mixture of clay is hand-thrown into sanded molds, without the use of machines to compact or cut them. Hardening can be either a sun drying or firing in a kiln at high temperatures. They are known for their unique textures, wavy edges, and rough finish, and are often used in construction for their strength, durability, and aesthetic appeal. Each handmade brick has a distinct pattern on its face, resulting from the hand-throwing technique. Handmade bricks are generally less

expensive than machine-cut bricks. Although the production of these bricks is labor-intensive and time-consuming. After drying, they are fired in a kiln or oven at high temperatures to harden and strengthen them.

This process also gives them their characteristic reddish-brown color & makes them chemically stable & inert.Handmade Bricks (Texture Bricks) can be used in various applications such as Structural walls, exterior and interior walls, Load Bearing and RCC constructions, Chimneys and fireplaces, Porches and terraces, Outdoor steps, brick walks and paved floors, etc. Because of these applications, Texture bricks have been an unremoved part of early civilization to modern revolution. Bricks can be joined using mortar, adhesives or by interlocking. Low maintenance, energy efficient, durable, affordable & highly attractive textures are some of the key advantages of handmade clay bricks. The color of fired clay bricks is influenced by the chemical and mineral content of the raw materials, the firing temperature, and the atmosphere in the kiln.

‘The Brick House’ offers more than 20+ types of handmade bricks crafted on Indian & western standards. The mostly sold sizes are 9” x 4” x 3”, 9” x 6” x 4” & 9” x 6” x 3” respectively. We do cater ‘London Stock Brick’ to our clients.

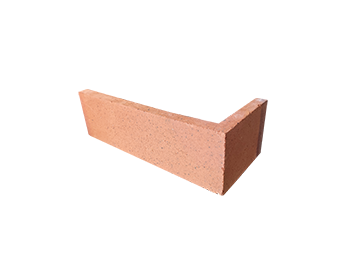

Cladding Tile

Cladding generally refers to a thin depth brick, mostly used on a plastered surface as a cosmetic or decorative element to improve or enhance the appearance of building. Terracotta cladding are generally preferred where one need to show an open & unplastered brickwork. These claddings gives walls a vintage & classy clay look. They may also be used to hide the faces of lintel, columns, beams or any undesired element made from cement.

Cladding tiles are used as a layer on top of the existing materials for walls, both interior and exterior that protect the spaces from weather changes, moisture and dampness. They can be used to protect the

building against heat & noise. Terracotta Cladding tiles are light in weight and do not load the building too much. They are easy to cut and handle, quick & easy to install. They are fire retardant as well. Thus these claddings are an energy saving material.

‘Terracotta’ means “baked earth”, so as the claddings which are fired in a kiln to make them strong & inert. They give a good freedom to use in various pattern to create an artistic appearance. These are an eco-friendly product & easy to recycle. They boost up the brickwork, thus saving the time of construction. Aesthetics & insulation are the two main purposes of cladding tiles.

At ‘The Brick House” Terracotta Cladding tiles are available in 30+ colors & in plain & rusticsurf ace finish. These colors are not a chemical colors but comes from a natural minerals present in clay. Our cladding tiles are best suited for elevations, facades & interior wall décor & are among the first choice for creating a unique facades. We have claddings made from a machine & manual hand having very long product life – cycle. Various sizes are available in claddings.

Being a product made from clay & exposed to the weather, they are highly absorptive to water & moisture. This absorption can be prevented or minimized by coating the surface of cladding with proper sealer liquid available in market. We also provide such solvents to clients to make their

walls water-proof.

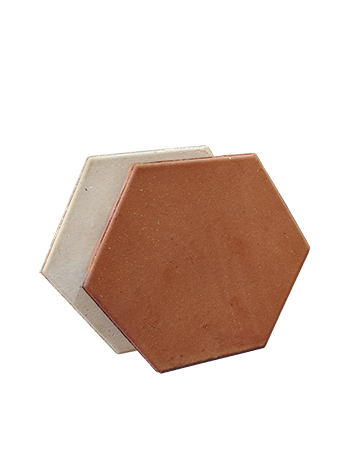

Flooring Tile

Clay Floor Tiles, known as Terracotta Floor Tiles or Weathering Tiles, are durable, ecofriendly tiles made from natural, fired clay, offering a warm, rustic aesthetic with variations in earth hues, and a cooling effect underfoot. Terracotta Floor Tiles are fired at a relatively low temperature

(around 1,000 degrees Fahrenheit), and its surface remains quite porous unless it is glazed. Clay Floor Tile are readily available and less expensive than many other ceramic forms.

Their porous nature requires sealing to prevent water absorption and staining. They are easy to maintain with regular sweeping and mopping. With our sealant applied, they are resistant to water and other liquids making them suitable for various uses. They are good insulators to heat & resistant to fire as well.

Terracotta pavers (also known as brick pavers or Clay Pavers) are made from fired clay that are known for their durability, color and can withstand a variety of conditions, including freeze-thaw cycles, abrasion, corrosion, and low water absorption. They are resistant to acids & alkalis. Pavers are typically placed on top of a foundation made of compacted stone and sand. The pavers are then placed in a pattern, and the space between them is filled with polymeric sand or mortar. Terracotta pavers keep the exterior clean and leave it as the earth itself. Clay pavers neither absorb nor radiate the heat, thus providing thermal comfort and aesthetically pleasing walkways or courtyards. Choose terracotta pavers, which do not interrupt the natural flow of water and air and let nature co-exist with you. Terracotta pavers are typically orange to reddish-brown in color. The color is determined by the clay material, firing time, and temperature. But at ‘The Brick House’, we offer clay pavers in various other colors as well, such as, Beige, Brown, Coffee, Dark Grey, White, Maroon etc. The color of Terracotta paver are same throughout & never fades as they are obtained from firing of clay in kiln & not from any coloring agent or chemical. Clay Pavers are commonly used for paving gardens, patios, terraces, walkways, driveways, and parking lots. It is perfectly resistant to high temperatures, but also to frost, torrential rain, shocks and UV rays.

‘The Brick House’ offers high thickness & low thickness floor tiles with respect to sizes, shapes, colors, surface textures & fuels used for baking. Mostly the size is 6” x 6” / 9” x 9” / 12” x 12” in square shape while 4” x 8” in rectangular shape. We also cater Hexagonal Clay Floor tile. Our Tiles are crafted on advanced machines, giving them a high level of precision & consistency.

Roofing Tile

We @ The Brick House, basically offers two types of Roofing Tiles, the one in Terracotta Clay & the other in Ceramic. Further, Terracotta Clay Roofing Tiles are offered in Mangalore Tiles, Roman Roofing Tiles, Penta Roofing Tiles & Decorative Tailor Tile. These are a roofing element of a building structure, made of clay and are a popular traditional roofing material. They are used to provide ventilation of air & insulation of heat. Some of them are especially made to be used for roofing kitchens, allowing smoke to escape, and bathrooms. They have double and single grooves, which give a pleasing appearance and also work to interlock the adjacent tiles.

Clay tiles are commonly used in coastal areas and regions that experience heavy rainfall. Whereas, they can also be used anywhere worldwide. These tiles for a sloping roof offer water proofing in areas where it rains quite often. The Mangalore tiles are generally placed inclined at forty five degrees. More the slope is, better the look is. Availability of technicians to install and maintain Mangalore roofing tiles is very easy & simple. They can be kept interlocked or overlapped, screwed

or jointed with cement mortar.

Clay Roofing tiles offer natural solar insulation, thereby reducing the expense on electricity for heating or cooling. Mangalore tiles can be installed on a metal fabricated structure, wooden frame or an RCC slope

roof for decoration purposes. Since these clay tiles are molded under extreme heat, they are resistant to destruction from fire. Decorative Roof Tiles or a Tailor Tile are customizable, durable building materials offered in various sizes, materials & finishes for interior & exterior use, providing excellent weather resistance & low maintenance, ideal if the roof area is small or an extension line a sunshade. Decorative roof tiles are available in multiple pattern to match the structures design. They are easy to clean & maintain, retaining their appearance and function with minimal effort Depending on the quality, Terracotta roofs can last as long as 50-60 years if they’remaintained properly. Mangalore Roof Tiles have been the most popular roof tiles for decades. Hence, we also sell a solvent base liquid to make tiles resistive to water absorption. At ‘The Brick House’, sizes available are 9” x 15” & 10” x 16” respectively. We also offers the Ceramic Roofing Tiles & their accessories with a complete range in 5 colors. These Ceramic or Spanish Tiles are 100% waterproof, Damp Proof & Sunlight Reflective, thus keeping the room temperature cool. These tiles are lighter in weight comparing with the cement roofing tiles in the same volume. With proper packing & committed delivery, we would love to cater you!

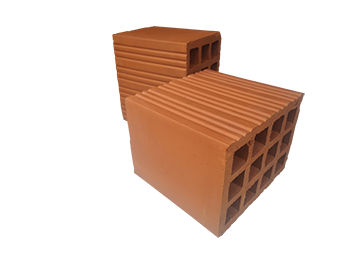

Hollow Blocks

The Hollow blocks are cost- effective, efficient & durable construction material, which also offers ease in handling, good thermal insulation & faster construction. The Horizontally Perforated Clay Hollow Blocks are primarily used as an infill masonry for non-load bearing wall construction. The product is especially beneficial for high rise apartment buildings, Houses, Hospitals, Educational Institutions, and Commercial Buildings etc.

The Vertically Perforated Clay Hollow Blocks are ideal for up to Ground+1 floors. The high compressive strength of these blocks enables the load bearing construction. This concept eliminates the columns which helps save the structural costs. These blocks can also be an excellent replacement to AAC blocks and conventional bricks.

Perforations in hollow blocks entrap air and provide excellent thermal insulation that’s 45% better as compared to conventional walling material. They keep the interior areas cool in summers and warm in winters. The perforation in the blocks act as a soundproofing system as well. The hollow blocks are 100% natural walling material; 40% less clay is used to make horizontal hollow blocks than conventional bricks. The wastage of blocks is as low as 2%, which means you can optimize the number of blocks required for construction

Our Clay Hollow blocks are fired at 1000 degree Celsius and have <11% water absorption that prevents water seepage into the building and dampness on the walls. It’s also easy to chase and chisel for electrical and plumbing conduits making it simple to install all types of fixtures. Perforated clay hollow blocks are more than 50% lighter in weight than conventional walling material thus allowing substantial savings on structural cost due to reduction in dead load. We offer both types of blocks, the one with 4 Face Lining & the other with 2 Face Lining & 2 Face plain.